Extract Engineering have the most up to date and comprehensive common rail diesel fuel injector test equipment in Cumbria. We can test all common rail diesel injectors. These include the latest designs of common rail injectors manufactured by VDO, DENSO, Delphi and Bosch – including the smart piezo designs.

The Hartridge Fuel Injector Tester Advantage

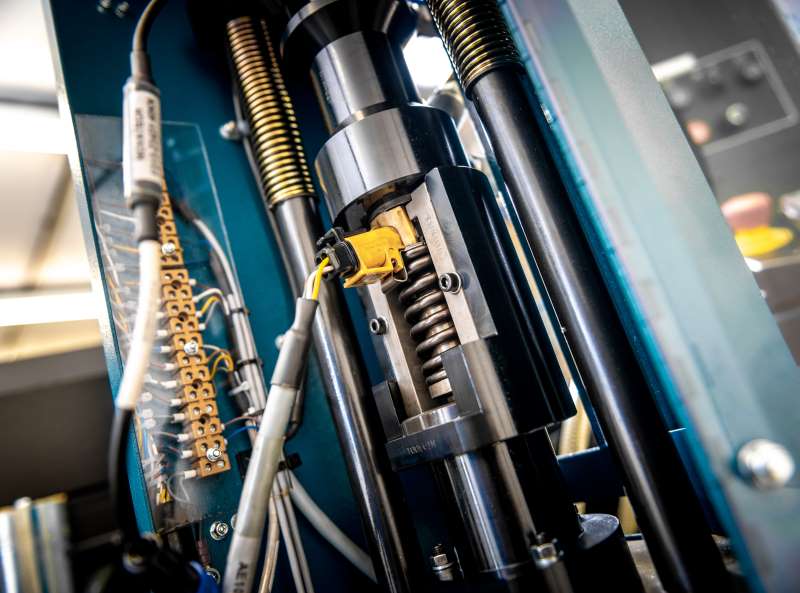

We have invested heavily in the latest Hartridge Sabre CRi Expert, which is the most advanced multi brand test machine on the market. We also use the Corona Test Equipment complete with its smart piezo facility. This commitment makes sure that you receive the most accurate test results available in the industry, right here in Carlisle.

We aim to become the centre of excellence for all common rail diesel users across Cumbria, North West of England and Southern Scotland.

How We Test Common Rail Systems

Extract Engineering's fuel injector flow testing process is very comprehensive. Prior to a full injector test on one of our test benches, we initially test solenoid injectors with the Delphi YDT720 and piezo injectors with the Bosch FSA 050 electrical test machines. These tests ensure that the injectors insulation, inductance and resistance are within specified limits.

Hartridge Sabre CRI Expert

The Hartridge Sabre CRI Expert test machine incorporates features which have been designed to future proof testing in an ever-changing market. It allows us to test existing and emerging common rail technologies at very high pressure, up to 2700 bar (39000 psi).

We can now test the following types of injectors -

- Delphi Euro 6 & Bosch CRIN 4.2 twin coil injectors, which are increasingly being used in all types of commercial vehicles.

- Delphi Euro 4 injectors

- The latest Bosch 117 family injectors

- Denso I ART injectors.

Upon completion of the injector test, we provide a very comprehensive test report. This includes results on fuel delivery, back leak, response time, nozzle opening pressure and minimum drive pulse and new coding if required.

Corona Test Bench

During test, each injector is run continuously at up to 2000 bar constant pressure. That is the pressure delivered by modern common rail fuel systems. This ensures correct atomisation and clean combustion to meet modern day emissions standards.

Measurements are taken over 2000 counted engine revolutions. This system allows us to take multiple measurements at different pressures throughout the entire injection process, including the IMA delivery both pre and post dead centre.

Upon completion of the injector test, we provide a comprehensive test report. This includes results from multiple injection events. These include fuel delivery, back leak, nozzle opening pressure and IMA start

We are more than happy to discuss these results with you in detail and offer you the most cost-effective solution to your issues, whether that is reconditioning your existing injectors or supplying new injectors.

By testing your injectors and ensuring they are within specification your fuel efficiency and therefore emissions will be improved on your diesel vehicle.

DIESEL INJECTOR RECONDITIONING SERVICE

We also offer an in-house injector reconditioning service. Faulty injectors are stripped, undergo an intense ultrasonic cleaning process and are reset using genuine parts where available.

This service comes with a one-year guarantee as standard, subject to terms and conditions.